We produce medical devices in production premises and clean rooms classified according to

ISO 14644-1 in class 8 using the following manufacturing techniques:

Injection molding our injection molding machines have a capacity of 30 to 320 tons. The machines are electric and most of our machines are placed in class 8 cleanrooms.

Our ambition is to be the natural choice when it comes to injection molding of complex and demanding details. We can make both long and short runs and we are proud being able to deliver high quality parts quickly and reliably.

Thermoforming the most cost-effective solution for thin-walled products in large volumes.

Injection blow molding a combined process of injection molding and blow molding for products that require high precision while blow molding technology is a requirement. In volumes up to 1 liter.

Blow molding our blow molding machines produce parts that, among other things, consist of a hollow body and thus cannot be injection molded in volumes up to 1 liter.

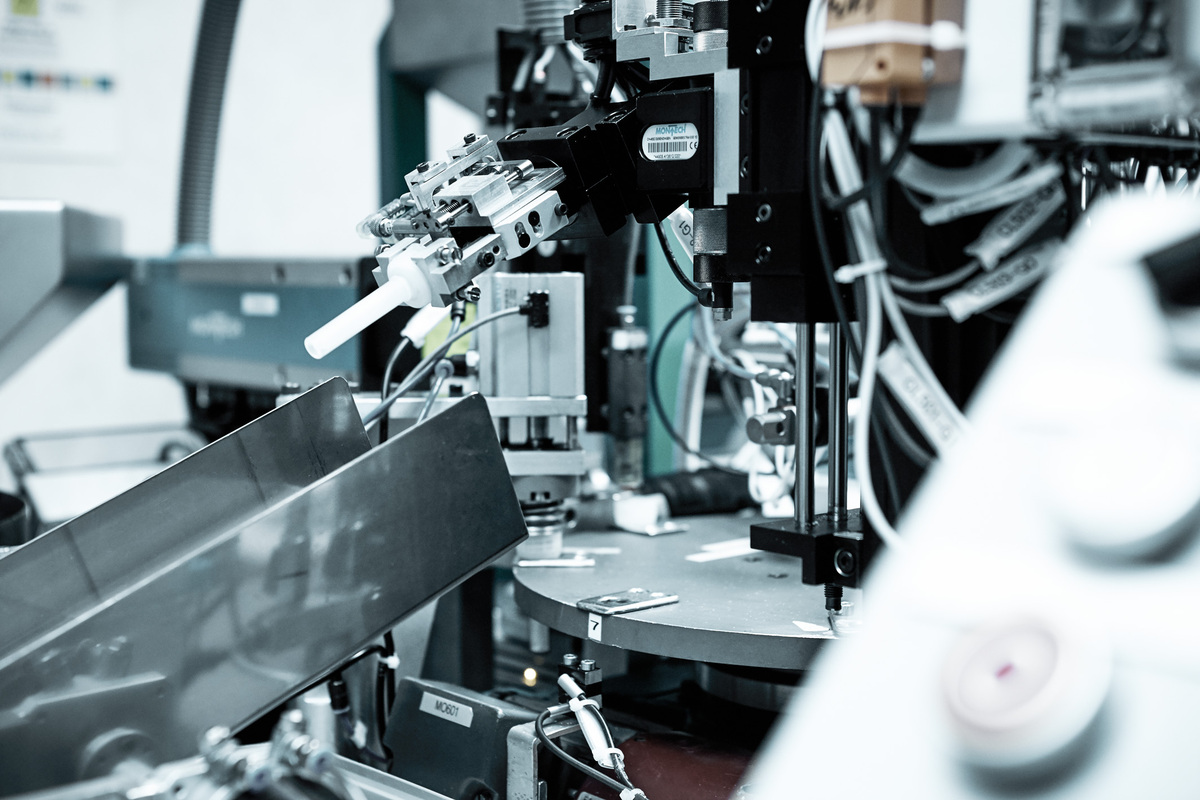

Automation cost effective solutions for small, medium and high-volume products.

Hpm™ One Solution Manufacturing Sites

Hammarplast Medical have medical production- and R&D units in several locations:

- Lidköping: Advanced production of large volume polymer medical disposables. We produce in top modern injection molding and thermoforming cells.

- Bredaryd: Injection molding and blow molding in clean room within pharmaceutical, diagnostics, surgery and the dental industry.

- Tallinn: Cost efficient and advanced assembly of complex medical devices and systems in clean room environments.